Embark on a journey into the heart of CO2 laser technology, where precision meets power in the workshop’s most versatile tool. This guide isn’t just about picking a laser cutter; it’s about understanding the beast that’s going to transform your workbench into a wizard’s lab.

Understanding CO2 Lasers

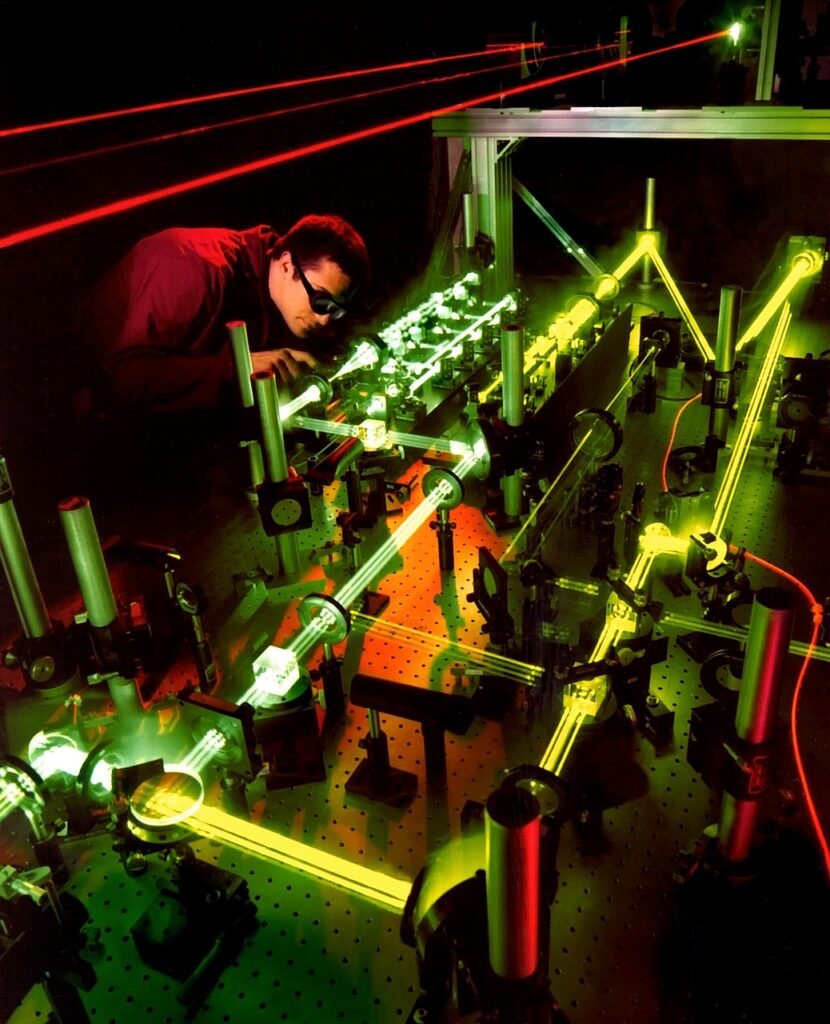

At its core, a CO2 laser is a marvel of physics, harnessing the power of light amplified through a gas mixture predominantly composed of carbon dioxide. When electricity runs through this gas mix, it excites the CO2 molecules, causing them to emit photons. These photons are then reflected back and forth in the laser tube by mirrors, gaining energy with each pass. When they’re finally directed out of the tube through a focus lens, they emerge as a concentrated beam of infrared light. This beam is so intense it can cut, engrave, or mark a multitude of materials by vaporizing them upon contact.

The beauty of CO2 lasers lies in their wavelength, around 10.6 micrometers, which is ideal for interacting with non-metallic materials and coated metals, offering unparalleled versatility in applications from crafting to industrial manufacturing.

Important Considerations Before Choosing a CO2 Laser

Selecting a CO2 laser requires more than just measuring your workspace. You need to consider the ventilation system to extract harmful fumes produced during cutting or engraving, especially when working with plastics or coated metals. Safety measures, including protective eyewear and fire prevention, are paramount, given the laser’s intensity. Additionally, the variety of materials you plan to work with will dictate the power requirements of your laser. Metals, for instance, can be marked or cut only when coated with a special treatment, as the CO2 laser beam typically reflects off bare metals.

Power Ranges and What They Mean for Cutting

Power is king in the world of CO2 lasers, with options ranging from 40W, ideal for engraving and cutting thin materials, up to 150W, capable of slicing through thicker mediums like wood and acrylic with speed and precision. The power of your laser affects not just the thickness of materials you can cut but also the speed of your work, allowing for faster production times with higher wattages. However, more power also means higher costs, both upfront and in terms of maintenance.

Size Matters: Understanding Different CO2 Laser Sizes

The physical size of CO2 lasers ranges dramatically, affecting both the maximum material size you can work with and the machine’s footprint in your space. Desktop models are compact and suitable for small businesses or hobbyists, while larger, industrial-grade machines require dedicated spaces and can handle extensive production runs with larger material sizes.

CO2 vs. Diode Lasers: The Clear Difference

The choice between CO2 and diode lasers boils down to your project needs. Diode lasers, operating at a different wavelength, are excellent for their compact size and entry level price tags but can struggle with clear materials and thicker cuts. In contrast, CO2 lasers excel in cutting efficiency and versatility, especially with materials like translucent acrylic, and glass, which are not possible to cut with most diode lasers.

Cooling Systems: Keeping Your Laser Chilled

Cooling is crucial for the longevity and performance of your CO2 laser. Lower-powered models may suffice with air cooling, but higher-powered machines typically require water cooling systems or external chillers to dissipate the heat generated by the laser tube. These cooling solutions ensure the laser operates within optimal temperature ranges, preventing overheating and potential damage to the system.

Popular Models and Price Ranges

Exploring brands such as Monport, OMTech, XTool, and Glowforge reveals a spectrum of CO2 laser cutters tailored to various needs and budgets. Entry-level machines from Monport offer affordability for hobbyists, while OMTech and XTool cater to a mid-range market with a balance of price and performance. Glowforge stands out for its user-friendly interface and community support, ideal for beginners and enthusiasts alike, but they lock you into their ecosystem. Prices vary significantly, reflecting differences in power, size, and features, from under $500 for basic models to over $10,000 for premium options

Software: The Digital Pulse of Your CO2 Laser

The software is the heart that pumps life into your CO2 laser’s capabilities, transforming digital designs into physical masterpieces. It’s the interface through which your creativity flows into the machine. Here are the essential points to consider:

- User Interface and Capabilities: The balance between a user-friendly interface and advanced capabilities is crucial. While some software prioritizes simplicity for beginners, others offer a rich set of features for experienced users willing to climb the learning curve.

- Software Subscription Models: A pivotal aspect of the total cost of ownership is whether the laser’s software operates on a subscription model. This ongoing cost can affect long-term affordability and access to advanced features, making it an essential factor in your decision-making process.

- LightBurn Compatibility: Compatibility with LightBurn, the industry-standard software, offers flexibility, a comprehensive feature set, and a supportive community. It’s a hallmark of versatility, allowing users to operate within a familiar and powerful software environment.

- Updates and Community Support: The frequency of software updates and the quality of community support are indicators of a software’s longevity and utility. Regular updates ensure compatibility with new operating systems and hardware, while a robust user community can be an invaluable resource.

The Cost of Ownership

Understanding the full cost of owning a CO2 laser extends beyond the initial price tag. It includes maintenance, consumables like lenses and mirrors, and crucially, the software that powers your laser. The choice between a one-time purchase and a subscription model, the compatibility with industry-standard software like LightBurn, and the availability of updates and support all contribute to the total cost of ownership. These software-related costs can significantly impact your experience and the long-term viability of your laser cutter.

Final Thoughts on Selecting Your CO2 Laser Cutter

Deciding on the right CO2 laser cutter is more than just a journey through the specs and capabilities of different machines. It’s about envisioning the future projects that will come to life under the beam of your new tool. The process intertwines technical specifications with software considerations, maintenance expectations, and, most importantly, your creative aspirations and practical needs.

Taking the time to consider what products you want to create or problems you wish to solve with the laser will ultimately guide you to the machine that’s right for you. Whether you’re aiming to start a small business, expand an existing one, or simply explore a new hobby, the applications of your CO2 laser cutter are as varied as the materials it can transform. Reflecting on your goals can help narrow down the choice by aligning the machine’s capabilities with your aspirations.

Ultimately, the right CO2 laser cutter for you is one that not only fits within your budget and workspace but also supports your creative journey and grows with you. It should be a tool that feels like a natural extension of your creativity, capable of bringing your most ambitious projects to fruition with precision and ease.

As you stand at the crossroads of innovation and creation, remember that the choice of a CO2 laser cutter is a step towards realizing your potential as a maker. With the right machine, supported by a software ecosystem that matches your workflow and ambitions, you’re not just choosing a tool—you’re unlocking a world of possibilities. Let this comprehensive guide light your way as you embark on a transformative journey with CO2 laser cutting, and prepare to explore the vast horizons of what you can achieve.

| Feature | Details |

|---|---|

| Power Ranges | 40W to 150W, affecting material thickness and cutting speed |

| Sizes | Ranging from desktop to large industrial models |

| CO2 vs. Diode Lasers | CO2 for versatility and material range, diode for compact size and cost |

| Cooling Systems | Air cooling for low power, water cooling for high power |

| Popular Models | Monport, OMTech, XTool, Glowforge |

| Price Ranges | $500 to $10,000+, depending on power and features |

| Software Considerations | User interface, subscription models, LightBurn compatibility, updates, and community support |

| Cost of Ownership | Maintenance, consumables, and cooling system upkeep, software subscriptions |