Laser engraving opens a universe of creative possibilities. With a laser engraver, you can leave your unique mark on a vast range of materials. However, understanding the nuances of these materials is key to achieving optimal results. This guide will explore the vast landscape of laser-engravable materials and empower you to make informed choices for your projects.

Understanding Laser-Material Interaction

Before delving into specific materials, let’s understand the basics of how they interact with the laser:

- Absorption: The material absorbs the laser’s energy, converting it into heat. This heat causes the material to vaporize or change color, creating the engraving.

- Wavelength: Different laser types (CO2, fiber) have different wavelengths, affecting how materials absorb the energy. CO2 lasers are most common for hobby engraving.

- Power and Speed: These laser settings control the intensity and duration of the beam’s interaction with the material.

Popular Hobby Laser Engraving Materials

- Wood: The Versatile Favorite

- Types: Hardwood (maple, walnut, cherry) offer clean engravings, while softwoods (pine, cedar) may burn more easily. Plywood is convenient and affordable.

- Considerations: Grain patterns, knots, and sap can affect results. Consider sealing wood to prevent scorch marks and enhance contrast.

- Acrylic: Precision and Color

- Types: Cast acrylic cuts cleanly and engraves with crisp edges. Extruded acrylic is cheaper but may melt when cut. Acrylic comes in a wide variety of colors and transparencies.

- Considerations: Use settings appropriate for your acrylic type. Watch for excessive flaming or melting, and ventilate well due to fumes.

- Leather: Timeless and Tactile

- Types: Real leather engraves beautifully, while faux leather can be less consistent. Consider the thickness and leather type for optimal settings.

- Considerations: Mask leather to reduce smoke residue. Some leathers may contain chemicals that release hazardous fumes when engraved.

- Glass: Elegance Etched

- Considerations: Engraving creates a frosted effect, not deep cuts. Glass requires special techniques, like applying a wet paper towel or masking tape, to prevent cracking.

- Anodized Metal: Durable Markings

- Considerations: The laser removes the anodized coating, revealing the metal beneath. True metal etching requires a fiber laser. Some anodized metals contain materials unsuitable for lasering.

Expanding Your Horizons

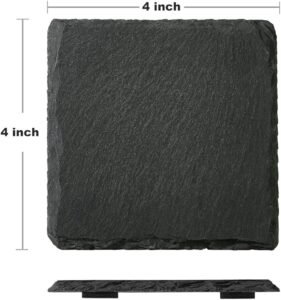

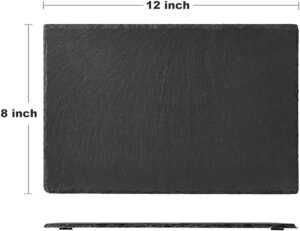

- Stone and Tile: Create unique engravings on natural stone or ceramic tiles. Settings may require experimentation for optimal results.

- Paper and Cardstock: Customize cards, decorations, and paper crafts with intricate laser engravings. Watch for burning with thinner materials.

- Fabric: Add personalized touches to textiles. Natural fabrics typically laser better than synthetics, which can melt.

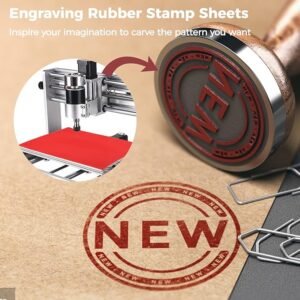

- Rubber Stamps: Create custom stamps with laser-safe rubber.

- Painted Canvas: Create amazing works of art by layering coats of spray paint and lasering them off to create beautiful effects.

Factors Affecting Your Material Choice

- Project Goals: Decorative, functional, or both? Consider durability, appearance, and intended use.

- Budget: Materials have varying costs. Balance price with the desired outcome.

- Laser Capabilities: Your laser’s power and type will influence compatible materials and achievable results.

- Safety: Be aware of materials that produce harmful fumes when laser engraved.

Tips for Success

- Test Cuts/Engravings: Always test on a scrap piece to dial in the ideal settings.

- Ventilation: Proper ventilation is crucial, especially when working with plastics or other materials that produce fumes.

- Experiment and Explore: The versatility of laser engraving encourages trying new materials. Keep records of your settings for future reference.

Remember: Material selection is an exciting part of the laser engraving journey! By understanding your options, considering project requirements, and a willingness to experiment, you’ll transform ordinary materials into extraordinary creations.